Economical and convenient V-bottom bags for on-the-go consumption. Perfect for french fries, churros, sandwiches, and grocery items.

Trusted by 30+ Partners

Our sharp bottom (V-bottom) paper bags are the staple of the street food and grocery industries. Gangda Packaging manufactures millions of these economical grocery paper bags and street food pouches monthly. Whether you need triangle paper bags for sandwiches or cone shape bags for fries and popcorn, our automated production lines ensure rapid delivery and consistent quality.

These bags are designed for easy dispensing and holding, making them ideal for fast-paced food environments. We use lightweight yet durable Kraft paper that can be plain or custom printed with your brand’s messaging. They are a fully recyclable alternative to single-use plastics, aligning with global environmental regulations.

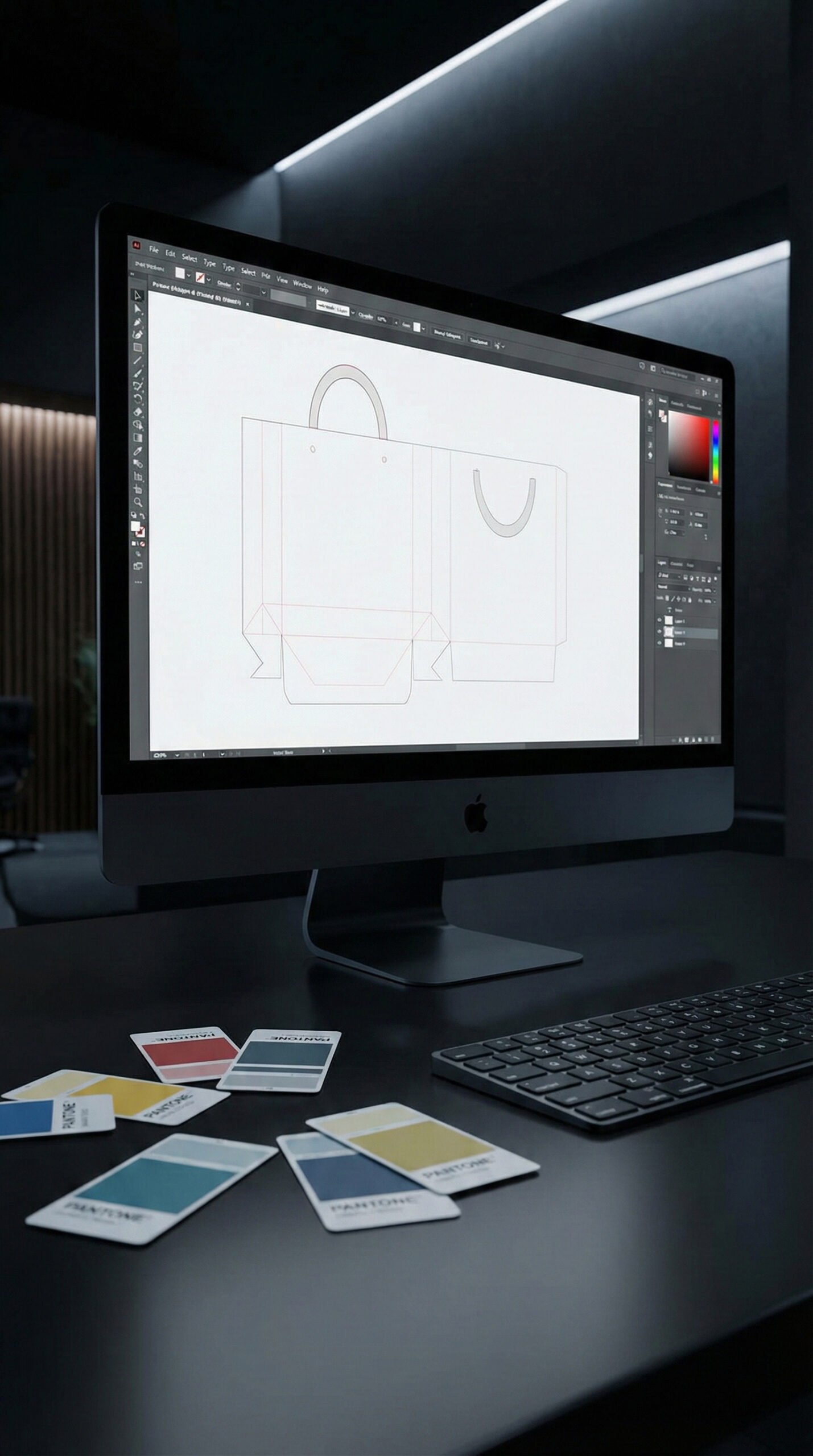

Reviewing your vector files (AI/PDF) to ensure print clarity.

Visualize before production. We generate a rotatable 3D render of your bag within 24 hours to confirm logo placement.

Touch and feel the quality. We mail a physical sample to your office for you to verify paper texture and color accuracy.

Heidelberg offset printing begins. The process includes printing, lamination, gold foil stamping, and manual assembly.

Final inspection before shipping. We ensure every bag meets standards. Goods are packed in rigid cartons and shipped globally.

Fully automated production for consistent quality and high output.

Tailored patterns, shapes, and branding to fit your market needs.

FSC certified and biodegradable paper options available.

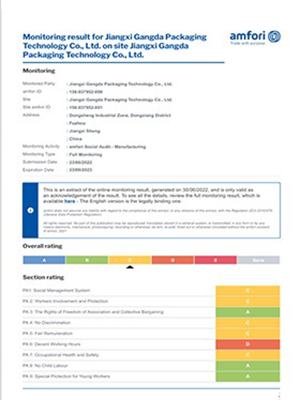

Strict ISO & SGS standards inspection before every shipment.

Efficient logistics to USA, Europe, and 50+ other countries.

Insights into our products and manufacturing.

Get a competitive factory quote and free samples for your next order.