Specialty Bags targeted solutions for healthcare, travel, and eco-friendly shopping. Reliable manufacturing for specialized industry needs.

Trusted by 30+ Partners

Gangda Packaging extends its expertise to specialized sectors with products like pharmacy paper bags and sickness (vomit) bags. These specialty bags require strict adherence to hygiene and functional standards. Our sickness bags are leak-proof and widely used by airlines and hospitals. Additionally, we produce non-woven shopping bags, offering a durable, reusable alternative to single-use plastics.

We also manufacture specialty bags like insulated thermal bags (aluminum foil lined non-woven) for the food delivery industry. Our diverse production capabilities allow us to serve niche markets with the same level of quality and customization as our standard lines, ensuring we are a one-stop solution for all your packaging requirements.

Reviewing your vector files (AI/PDF) to ensure print clarity.

Visualize before production. We generate a rotatable 3D render of your bag within 24 hours to confirm logo placement.

Touch and feel the quality. We mail a physical sample to your office for you to verify paper texture and color accuracy.

Heidelberg offset printing begins. The process includes printing, lamination, gold foil stamping, and manual assembly.

Final inspection before shipping. We ensure every bag meets standards. Goods are packed in rigid cartons and shipped globally.

Fully automated production for consistent quality and high output.

Tailored patterns, shapes, and branding to fit your market needs.

FSC certified and biodegradable paper options available.

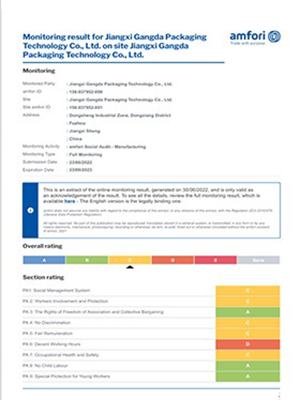

Strict ISO & SGS standards inspection before every shipment.

Efficient logistics to USA, Europe, and 50+ other countries.

Insights into our products and manufacturing.

Get a competitive factory quote and free samples for your next order.